Review - Modern Phytomorphology ( 2022) Volume 16, Issue 2

Enhancement of strawberry shelf life with coating: A review

Komalpreet Kaur1* and Anil Kumar22Department of Vegetable Science, Lovely Professional University, Punjab, India

Komalpreet Kaur, Department of Food Science and Technology, Lovely Professional University, Punjab, India, Email: komalpreet4111@gmail.com

Received: 10-May-2022, Manuscript No. mp-22-63421; Accepted: 01-Jun-2022, Pre QC No. mp-22-63421(PQ); Editor assigned: 11-May-2022, Pre QC No. mp-22-63421(PQ); Reviewed: 25-May-2022, QC No. mp-22-63421(Q); Revised: 27-May-2022, Manuscript No. mp-22-63421(R); Published: 09-Jun-2022, DOI: 10.5281/zenodo.7735668

Abstract

As the world population is increasing and the requirements for the fruits and vegetables is also increasing all around the world. According to year 2018, fruit production has reached up to 7.1 million tonnes. Food stocks can be increased for future generations. Supply of food and accessibility can be increased by increasing demand, improving delivery, and reducing losses. Fruit’s perishable nature makes it susceptible to loss in post-harvested crops, particularly when it distributed for long distance. Applying coating to the fruit will help to reduce the amount of impoverishment. Different types of post-harvest coatings applied on fruits e.g. bananas, strawberries, mangoes, pineapples, and avocados which prolongs the storage survival, loss of water, chilling injuries loss. To satisfy the supply needs of future generations, food processing industries must prevent postharvest losses. To overcome these problems, number of techniques used to preserve the food product for longer duration of time. Methods like heat treatments, cold storage, coating, Nano emulsion, Nano technology etc. are the most popular around the world. Using the different types of additives in incorporated with the edible coating makes the food product more appealing, nutritious, inhibits microbial growth, increase the storage life. Several foods have been coated for enhancing these qualities into them. Whereas, it is also use in the bakery and confectionery industries. These films help to maintain the physical and chemical properties of fresh and highly processed fruits for a longer duration. This analysis demonstrates that edible film is a great method for extending tropical fruit's post-harvest life. Despite the research focus, further work is required, especially to better predict the process of biopolymer products until ingestion in order to provide a safe film for consumer use. With the help of this article, processors would be able to use this knowledge to choose the right coating material and density for various processed foods.

Keywords

Coating materials, strawberry, post-harvest losses, post-harvest diseases, chilling injury

Introduction

As we know, fruits and vegetables are the important component for human nutrition. Consumption of fruits and vegetables has been related to a variety of health benefits for humans (Tayyar et al., 2020). These have been playing an important role in our everyday diet from last few years, providing many health benefits. These are good sources of nutrients such as antioxidants, vitamins, minerals, flavonoids and fibers (Raghav et al., 2012). As these fruits and vegetables are living things that require O2 and produce CO2 in the process of respiration. Metabolism of materials such as fats, proteins, and organic acids, as well as carbohydrates, occurs during the respiration phase. As all the substrate gets metabolized, the supply becomes difficult because of the removal of fruit and vegetable from the plant and hence the quality parameters such as colour, flavour, weight and the nutritive content of the product will be affected (Tayyar et al., 2020). As these food products are highly prone to spoilage because of high moisture content (78%–89%) so reducing shelf life and resulting in financial loss (Sharma et al., 2019). According to recent studies, it observed that both metabolic and microbial activities are responsible for the deterioration of strawberry fruit during storage, which leads to the nutrients loss (Luo et al., 2020).

The most critical characteristics of fresh fruits for consumers are their flavour and colour, as well as their nutrient content and Strawberry is one of the most common fruits all over the world, with a distinct and highly appealing taste and flavour. The fruit of the strawberry plant (Fragaria x ananassa Duch) is one of the most popular and highly consumed berries around the world. In recent decades, global strawberry demand has risen by more than 80%, achieving more than 9 million tonnes in 2016. China and United States are the largest producers of the strawberry (Nunes et al., 2020). Strawberry is one of the most analysed genomic and agronomic berries because of its commercial, industrial and economical importance. The colour of the strawberries occurs from anthocyanins that accumulate through the maturation period. Despite the fact that strawberry is appreciated for their strong phytochemical content. This compound will act as good antioxidant and have the properties like anticancer, antimicrobial, anti-inflammatory, and antihypertensive properties. These are also good in vitamin C that aids in the prevention of diabetes mellitus, increases immune function, and slows the progression of leukaemia in humans. Aside from providing these nutrients, eating these plant-based diets will help to reduce several diseases like heart, cancer, stroke, Alzheimer’s disease, cataracts, and a decrease in age-related activity (Liu et al, 2013). Mature strawberries are highly prone to spoilage because of their smooth texture softening and respiration rates, and susceptibility to fungal attack and off-flavour growth (Yan et al., 2019). Few recent developments such as edible coating, ozone use and use of thermal technology are used for the prevention of fruits and vegetables from the post-harvest degradation. The process of coating and refrigeration can help to increase the storage life of several food products after harvesting (Riaz et al., 2021).

Need of Coating

Post-harvest losses during distribution/travelling

The Fruit and vegetable quality can be preserved but not increased after harvesting; thus, these must be harvested at the correct maturity level. Several disorders such as skin strains, cracks, spots, rots, and decay may occur as a result of improper care while harvesting, which enhances the microbial growth. The shelf life will be reduced with the increase in the loss of water and respiration rate from the product (Sharma et al., 2019). As we know, the fruits must be transported from one country to another via air and sea shipping to meet global demand. On the other hand, air transport takes less time than sea shipping but costs more. During the transportation of fruit over long distances, it is necessary to remember the storage conditions including temperature, CO2 and O2 level (Nor et al., 2020). While neglecting these circumstances will lead to the Post-harvest losses that are estimated between 15 and 50 percent in both industrialised and developing nations. This has an effect on both suppliers and customers. On the other hands, these errors can happen at any point during the delivery process including suppliers, dealers, and retailers. Which will decrease the fruit supply but transportation and selling costs per unit are increased (Murthy et al., 2009). The amount of fruit losses has been confirmed to arise throughout preparation and distribution. The solution to ensuring the consistency of fresh fruits and vegetables during transportation has been environmental regulation such as temperature and humidity control. Also handling and the packaging of the product are vital in maintaining the quality of fruit or vegetable (Cherono et al., 2018). The main loss that leads to the quality of fruit is the limited shelf life. Water deficiency, chilling burns, postharvest illness, and browning are all caused by the fruit’s inherent biological behaviour (Bodbodak et al., 2016). The preharvest factors are also responsible for the changes in the postharvest methods. Factors such as nutrients, water supplies and harvesting method are also effects the pre- and postharvest losses. This results in low market acceptance, fertiliser degradation, and economic damage for the farmers (Arah et al., 2015).

Post-harvest diseases

As we know bacteria and fungus are mainly responsible for the diseases caused in the post harvested crops. Basically Colletotrichum spp. damage a variety of tropical and subtropical fruit crops, which causes substantial disruption and declines in the yield of crop. Pathogens are also responsible for the contamination of pre and post-harvest foods cause diseases like leaf spot, flower rot, fruit rot, stem end rot, and root rot etc. Due to adverse environmental conditions fungal growth will occur, resulting in anthracnose disease in fruits (Supraman et al., 2019). Pathogen species Penicillium expansum L. can cause blue mold which can affect the several fruits like apple, pear, stone fruits, kiwifruit, many berries, pomegranate etc. On the other hand, disease sour rot is caused by Geotrichum spp., and Rhizopus spp., can leads to the disease soft rot. Also the pathogen, Botrytis cinerea Pers Fr. is the reason for the grey mold which is mainly occurs in fruits like grape, strawberry, kiwifruit, pomegranate, fig etc. Colletotrichum spp. can leads to Anthracnose and Alternaria spp., which causes black spot in several tropical and non-tropical fruits (Palou et al., 2018). The developments of wound on the surface of the fruit shoes the signs of infection were reddish brown fruit tissue, followed by blue-green in colour. Surface of the fruit can be sterilized by using 2% sodium hypochlorite for 1 minute and flushed three times in deionised water, wiped dry for 45 seconds (Ghuffar et al., 2018). Toxins produced by fungi, such as aflatoxin, can develop in contaminated fruits and quickly cause food poisoning. Gray mould is a dangerous disease is caused by a pathogen called B. cinerea in different plant varieties and crops stored in pots, like strawberry, apple, oranges etc. Whereas, using different chemical compounds such as thiabendazole, benomyl etc. is used to inhibit the increase in the number of gray mold in postharvest crops. But these chemicals are restricted in some of the countries. To overcome these problem, natural products such as plant extracts and essences have been used to combat fungal pathogens in preserved fruits has become a viable option for fruit growers (Gholamnezhad et al., 2019). Also the phytochemical substances are also known as good antifungal for crop protection (Cabral et al., 2013). While acidic formulations of certain GRAS salts have antimicrobial efficacy, which is highly soluble and it is used in the edible coating to increase the shelf life of the fruits (Palou et al., 2018).

Environmental factors

The light, heat, moisture all serve a significant role in extending the storage life of fresh harvest. Metabolic activity of fruits and vegetables is increased at high temperatures, resulting in a shorter shelf period and also these fluctuations in temperature can leads to the loss of water activity, flavour (Sharma et al, 2019). Ethylene is a gaseous phytohormone that regulates a variety of plant growth and production processes. Ethylene development rises dramatically during different periods of growth, such as fruit ripening, which affects several factors like physical injury, pathogen invasion, or high temperatures (Chang et al., 2008). Ethylene production in fruits and vegetables may also shorten the shelf life due to physical effects and increased storage conditions. Proper handling can protect the product from physical or biological injury, preventing tissue degradation and other deteriorative processes thereby increasing the rate of respiration and softening of the tissues (Mutari et al., 2011).

Water loss

Fresh fruit and vegetables has a high water content during harvesting, ranging from 80 to 95 percent, giving it a fresh look and firm texture. During post-harvest handling, the produce continues to lose water which will leads to the shrinkage, wilting, and unwanted texture variations. Since the lack of water lowers their economic worth by reducing the amount of weight that can be sold. In certain studies, it is said that the transpiration mechanism is related to improvements in texture attributes and apparent wrinkling of the fruit skin (Pereira et al., 2017). Modest loss of moisture will only change the colour and skin layer of the product, while threshold moisture loss will change the turbidity, firmness, discoloration, flavour, and nutritional value. Additionally, increased weight loss can cause chilling injury and raise pathogen invasion. The amount of water loss varies greatly between various fruits and vegetables even though these preserved under the same climatic conditions (Nunes et al., 2007). A study of method of spraying coconut water on the dragon fruit is conducted which helps to enhance its bright red colour. The presence of hormone called cytokinins which help to retain the colour at 20℃ for 11 days (Rodeo et al., 2018). Also coating is one of the very popular ways to inhibit the water loss, preserving the ability of peel tissue, maintaining the volatile elements of fruit, and adjusting CO2 and O2 concentrations within the fruit. It also maintains the colour of the fruit for longer duration (Li et al., 2018). Additionally, coating with antioxidant property also helps to maintain the water activity, fruit surface browning,slows the ripening process. The use of turmeric flour as an antioxidant keeps the banana fruit fresh for longer period of time (Paula et al., 2018).

Chilling injury

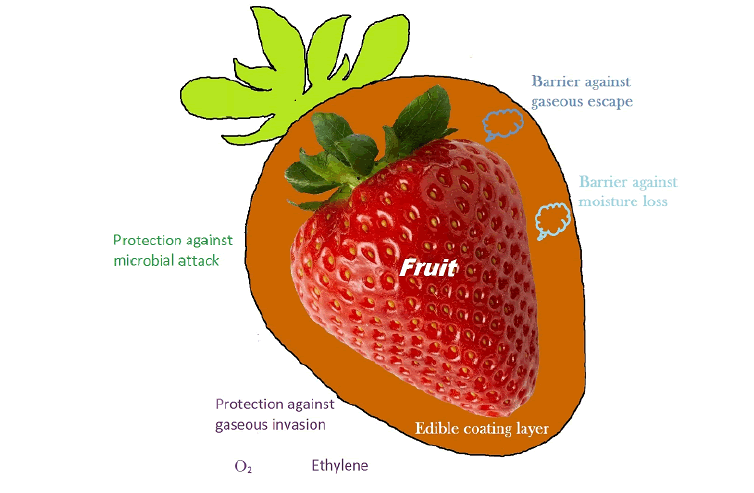

One of the most important considerations for the fruit maintenance is the temperature. Chilling injury is a physiologic condition caused by exposure to low temperatures above freezing temperature (CI). This phenomenon reduces the storage life of produce and causes major quality deterioration. Heat treatments (hot water dips, stimulated hot air and vapour) are used to delay ripening and cause CI resistance in a variety of fruits. For example: In the case of sweet persimmon, heat treatments were used to inhibit CI. The activation and behaviour of heat shock proteins is one proposed mechanism for induced tolerance (HSP). HSP is generated by heat treatment and prevents fresh produce from both heat injury and CI. HSP is also known as stress proteins (Manurakchinakorn et al., 2014). Fruit that has been kept at a lower temperature (1℃-4℃) and switched to normal room conditions will exhibit the chilling sign more often. Changes in the physical state of cell-membrane lipids are often linked to the condition (Wang et al, 2019). One of the most common signs of chilling injury in post-harvest banana fruit during cold storage is peel browning. The interaction of phenolics with Polyphenol Oxidase (PPO) and/or peroxidase has been mentioned as a cause of peel browning (POD) (Liu et al., 2019). The colour variations are caused by chlorophyll oxidation and the development of yellow tetraterpenoids as the plant matures. On the other hand, the increase in brown colour during storage may be due to oxidoreductase enzymes. Storing tropical fruits at the temperature between 10℃-15℃ can cause chilling injury and shows the symptoms like fruit as fruit drop, weight loss, pitting and brown scalding of the skin (Venkatachalam et al.,2016). (Venkatachalam et al., 2015) have stated that Chilling injury and fruit firmness loss were reduced when longkong fruit was treated with Methyl Jasmonate (MeJA) (30 mol L1) and stored at 13℃. MeJA can also reduce the increased enzyme activities of the fruits. (Zehedi et al., 2019) investigated the various qualitative and nutritional adjustments that occur in the fruit while ripening, including colour alteration, firmness, sugar and organic acid concentration, and differences in taste flavour, aroma, and biological materials. Edible coating from chitosen and polyamine spermidine has been developed to increase the consistency, protection, and durability of product. A semi-permeable membrane has been placed between the substance and the surrounding atmosphere as a barrier for vapour, oxygen, and carbon dioxide (Fig. 1).

Figure 1: The edible coating on strawberry fruit.

Advantages and Disadvantages

There are several good and bad impacts of edible coating on the food product. Generally, edible coatings help to biodegradability, safety and shelf life of the food product. It improves the physical strength and reduces the particle clustering. It helps to maintain the aromatic compounds, colour, appearance and several nutrients of the product. This technique also involves additives into food product and it is cheaper in cost. The use of edible coatings to change internal atmospheres can exacerbate problems related to high CO2 or low O2 concentrations. Whereas the main drawback of using the edible coatings is the change in internal atmospheres, which can exacerbate problems related to high CO2 or low O2 concentrations. When a coating is applied so thickly, it may have negative consequences. Coating compositions that allow for sufficient gaseous transfer are often ineffective as liquid water barriers. The creation of an internal changed environment is insufficient to have the desired preservative results, requiring the inclusion of a separate technology such as packaging (Turhan et al., 2009). On the other hand, the key benefit of using plasticizers in films to improve hardness, maintain mechanical properties, increasing durability and elasticity. Conversely, the increase film permeability is one of the main drawbacks of plasticizers. For example, water-soluble plasticizers, have a lower moisture barrier than Oil Permeability. Plasticizers can also susceptible to ageing, extraction, displacement, instability, and hydrolysis (Sothornvit et al., 2005).

Conclusion

To satisfy the supply needs of future generations, food processing industries must prevent postharvest losses. To overcome these problems, number of techniques used to preserve the food product for longer duration of time. There are number of different methods those are used to prevent the spoilage of number of fruits and vegetables all around the world, such as heat treatments, cold storage, coating, Nanoemulsion etc. Using the coating material enhances not only the shelf life but also make fruits and vegetables more nutritious. Addition of different additives can also help to increase the nutritive value, make food more appealing, inhibits microbial growth as well as increase the storage life. There are various foods those have been coated for enhancing these qualities into them.

Whereas, it is also use in the bakery and confectionery industries. These films help to maintain the physical and chemical properties of fresh and highly processed fruits for a longer duration. All these analysis demonstrates that edible film is a great method for extending post-harvest life tropical fruit’s as well as many vegetables and other foods. Despite the research focus, further work is required, especially to better predict the process of biopolymer products until ingestion in order to provide a safe film for consumer use.

References

Al-Tayyar N.A., Youssef A.M., Al-Hindi R.R. (2020). Edible coatings and antimicrobial nanoemulsions for enhancing shelf life and reducing foodborne pathogens of fruits and vegetables: A review. Sustainable Materials Technol 26: e00215.

Google Scholar Cross Ref

Raghav P.K., Agarwal N., Saini M. (2016). Edible coating of fruits and vegetables: A review. Education 1: 2455-5630.

Sharma P., Shehin V.P., Kaur N., Vyas P. (2019). Application of edible coatings on fresh and minimally processed vegetables: a review. I J Vegetable Sci 25: 295-314.

Sharma P., Kehinde, B.A., Kaur, S., Vyas, P. (2019). Application of edible coatings on fresh and minimally processed fruits: A review. Nutrit Food Sci 49: 246.

Luo P., Li F., Liu H., Yang X., Duan Z. (2020). Effect of fucoidan-based edible coating on antioxidant degradation kinetics in strawberry fruit during cold storage. J Food Process Preservat 44: e14381.

Nunes G., Teixeira F., Schwarz K., Camargo C.K., Resende J.T.V.D., Santos E.F.D., Novello D. (2020). Influence of genetic variability on the quality of strawberry cultivars: sensorial, physical-chemical and nutritional characterization. Acta Scientiarum Agronomy 43.

Nunes C.N., Emond J.P. (2007). Relationship between weight loss and visual quality of fruits and vegetables. In Proceedings of the Florida State Horticultural Society 120: 235-245.

Liu R.H. (2013). Health-promoting components of fruits and vegetables in the diet. Advances in Nutrition 4: 384S-392S.

Yan J., Luo Z., Ban Z., Lu H., Li D., Yang D., Li L. (2019). The effect of the layer-by-layer (LBL) edible coating on strawberry quality and metabolites during storage. Postharvest Biol Technol 147: 29-38.

Riaz A., Aadil R.M., Amoussa A.M.O., Bashari M., Abid M., Hashim M.M. (2021). Application of chitosan-based apple peel polyphenols edible coating on the preservation of strawberry (Fragaria ananassa cv Hongyan) fruit. J Food Process Preservat 45: p.e15018.

Nor S.M., Ding P. (2020). Trends and advances in edible biopolymer coating for tropical fruit: A review. Food Res Int 134: 109208.

Murthy D.S., Gajanana T.M., Sudha M., Dakshinamoorthy V. (2009). Marketing and post-harvest losses in fruits: its implications on availability and economy. Indian J Agricul Econom 64: 902-2016-67302.

Cherono K., Workneh T.S., (2018). A review of the role of transportation on the quality changes of fresh tomatoes and their management in South Africa and other emerging markets. I Food Res J 25: 2211-2228.

Bodbodak S., Moshfeghifar M. (2016). Advances in modified atmosphere packaging of fruits and vegetables. In Eco-friendly Technology for Postharvest Produce Quality 127-183.

Arah I.K., Amaglo H., Kumah E.K., Ofori H. (2015). Preharvest and postharvest factors affecting the quality and shelf life of harvested tomatoes: A mini review. I J Agron 2015.

Palou L. (2018). Postharvest treatments with GRAS salts to control fresh fruit decay. Horticulturae 4: 46.

Ghuffar S., Irshad G., Naz F., Rosli H.B., Hyder S., Mehmood N., Zeshan M.A., Raza M.M., Mayer C.G., Gleason M.L. (2018). First report of two Penicillium spp. causing postharvest fruit rot of grapes in Pakistan. Plant Disease 102: 1037-1037.

Gholamnezhad J. (2019). Effect of plant extracts on activity of some defense enzymes of apple fruit in interaction with Botrytis cinerea. J Integrat Agricul 18: 115-123.

Da Cruz Cabral L., Pinto V.F., Patriarca A. (2013). Application of plant derived compounds to control fungal spoilage and mycotoxin production in foods. I J Food Microbiol 166: 1-14.

Chang S.H., Lu L.S., Wang N.N., Charng Y.Y. (2008). Negative feedback regulation of system-1 ethylene production by the tomato 1-aminocyclopropane-1-carboxylate synthase 6 gene promoter. Plant Science 175: 149-160.

Mutari A., Debbie R. (2011). The effects of postharvest handling and storage temperature on the quality and shelf of tomato. African J Food Sci 5: 340-348.

Pereira E., Spagnol W.A., Silveira Junior V. (2018). Water loss in table grapes: model development and validation under dynamic storage conditions. Food Sci Technol 38: 473-479.

Li X., Zhu X., Wang H., Lin X., Lin H., Chen W. (2018). Postharvest application of wax controls pineapple fruit ripening and improves fruit quality. Postharvest Biol Technol 136 99-110.

Manurakchinakorn S., Nuymak P., Issarakraisila M. (2014). Enhanced chilling tolerance in heat-treated mangosteen. I Food Res J 21.

Wang Y., Ji S., Dai H., Kong X., Hao J., Wang S., Zhou X., Zhao Y., Wei B., Cheng S., Zhou Q., (2019). Changes in membrane lipid metabolism accompany pitting in blueberry during refrigeration and subsequent storage at room temperature. Frontiers in Plant Science 10: 829.

Liu, J., Li F., Liang L., Jiang Y., Chen J. (2019). Fibroin delays chilling injury of postharvest banana fruit via enhanced antioxidant capability during cold storage. Metabolites 9: 152.

Venkatachalam K., Meenune M. (2015). Effect of methyl jasmonate on physiological and biochemical quality changes of longkong fruit under low temperature storage. Fruits 70: 69-75.

Venkatachalam K. (2016). Postharvest physiology and handling of longkong fruit: A review. Fruits 71: 289-298.

Zahedi S.M., Hosseini M.S., Karimi M. and Ebrahimzadeh A., (2019). Effects of postharvest polyamine application and edible coating on maintaining quality of mango (Mangifera indica L.) cv. Langra during cold storage. Food Sci Nutrit 7: 433-441.

Turhan K.N. (2009). Is edible coating an alternative to MAP for fresh and minimally processed fruits?. In X International Controlled and Modified Atmosphere Research Conference 876: 299-305.

Sothornvit R., Krochta J.M., (2005). Plasticizers in edible films and coatings. In Innovations in food packaging 403-433.

Rodeo A.J., Castro A.C., Esguerra E.B. (2018). Postharvest handling of dragon fruit (Hylocereus spp.) in the Philippines. In Conference paper presented in Dragon Fruit Regional Network Initiation Workshop and Steering Committee Meeting, Taipei and Taichung, Taiwan pp: 125-131.